Applications

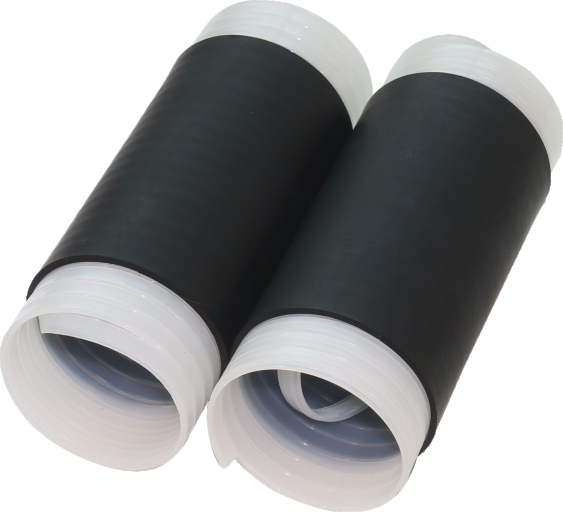

Heat shrinkable belt is designed specifically for buried or overhead steel tube joint anticorrosion material and design of heat shrinkable type anticorrosive repairing materials . It consists of radiation crosslinking hdpe base material and special sealed hot-melt adhesive coating compound and into Suitable for 3 PE , FBE , PP for anticorrosion of pipe line joint repairing and anticorrosive bend area , also can be used in the yellow jacket insulation pipe joint repairing . Special seal hot melt adhesive and PE base material , steel surface and liquid epoxy coating can form good bonding.

Features

Heat shrinkable belt installation construction . under the effect of thermal heat shrinkable belt along the radial uniform shrinkage , hot melt glue line to melt at the same time , uniform coating filled in the pipe surface , and the original pipeline anticorrosion layer form a continuous and compact system , can resist the soil stress , hy-drostatic pressure resistance , cathodic disbonding resistance , chemica lresistance and the erosion of the mold and other corrosion behavior.

Technical data

| SPECIFICATIONS | |||

| Property | Test Method | DM-SSW | |

| Operating Temperature | Up to 60℃ | Up to 80℃ | |

| Backing | |||

| Tensile Strength | ASTM D638 | 2,700 psi | 3,000 psi |

| Elongation | ASTM D638 | 650% | 650% |

| Hardness Shore | ASTM D2240 | 46 | 50 |

| Dielectric Strength | ASTM D149 | 20kV/mm | 20kV/mm |

| Volume Resistivity | ASTM D257 | 1x10'Q-cm | 1x10'Q-cm |

| Water Absorption | ASTM D570 | <0.05%(Wt) | <0.05(Wt) |

| Adhesive | |||

| Softening Point | ASTM E28 | 95℃ | 120℃ |

| ap Shear | ASTM D1002 | 140PSI@23℃ | 245PSI@23℃ |

| ap Shear | DIN EN12068 | 100N/cm²@23℃ | 170N/cm²@23℃ |

| nstalled Product | |||

| Peel Strength | DIN EN 12068 | 60N/cm @23℃ | 80N/cm @23℃ |

| mpact Resistance | DIN EN 12068 | >15J | >15J |

| Indentation Resistance | DIN EN 12068 | pass | pass |

| Cathodic Disbandment | DIN EN 12068 | <15mmrad. | <15mmrad. |

| RANGE: | |||

| Standard manufacturingrang range covers the following sizes and dimensions: | |||

| Dimension | Range | ||

| Sleeve width | Up to 720mm | ||

| Backing thickness (recovered) | 1.0mm to 1.5mm | ||

| Mastic thickness | 0.5mm to 1.5mm | ||

| Roll length | 10M,15M&30M | ||

specifications. Please contact us for guaranteed specifications.to meet your individual requirements.